The advent of electric vehicles represents a seismic shift in thinking as well as operations. In this thought leadership opinion piece, Thomas Goetzl from Keysight Technologies shares his insights on how this introduces several challenges like pressure on the power grid and a need for sustainable and environmentally friendly material.

Over the next decade, many automakers plan to transform their fleets to electric power, with some announcing goals for fully electric lineups within five years.

Automakers are making products that meet evolving industry standards for safety, emissions testing, and energy efficiency.

The surge in electric vehicles comes with infrastructure, manufacturing, and regulatory challenges that will impact the automotive industry.

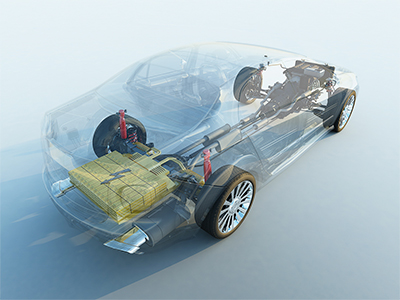

They require Electric Powertrain and HEV/EV solutions that address safety, regulatory, and environmental issues.

This significant transformation represents a seismic shift in thinking as well as operations and introduces several challenges like pressure on the power grid and a need for sustainable, environmentally friendly material.

Pressure on the power grid

The stark difference between the century-old technology of the combustion engine and that of battery-powered electric vehicles presents enormous obstacles, none more important than the power grid.

The energy and automotive sectors have operated independently since their inception.

The Advent of Electric Vehicles

In 2021, electric car sales surpassed 6.5 million.

That’s a 108 per cent increase from the previous year and a number expected to rapidly accelerate over the next decade, according to the International Energy Agency (IEA), a Paris-based intergovernmental organisation that monitors the global energy sector.

By the end of this decade, the IEA projects that more than 300 million electric vehicles will be on the road and account for 60 per cent of new vehicle purchases – up from 4.6 per cent of new car sales today.

While the electric vehicle marketplace has continued to grow, increased global government policies to reduce CO2 emissions and promote electric vehicle sales, such as the European Union CO2 emissions regulation for cars and vans, California’s Zero-Emission Vehicle (ZEV) mandate, China’s New Energy Vehicles (NEV) mandate, and the recent sharp increases in oil prices further highlight the coming change.

Electric vehicles, of course, require an electric charge to use, and EV charging stations, which could power a car in less than 10 minutes, but demand a tremendous amount of electricity.

IEA projects EV’s will account for 4 per cent of the total global electricity demand by 2030, an amount that is equivalent to double Brazil’s total current electricity use.

The volume of electric cars that will be added to the current grid presents a disaster recipe.

The existing electric grid has operated primarily on conventional power plants that offer a minimum level of baseload power generation that provides energy certainty.

Electric utilities have historically enjoyed steady and predictable load patterns with minimal variation, which helped simplify the task of balancing supply and demand of electricity.

However, moving from conventional power plants to renewable distributed energy resources (DER) such as solar and wind in the power grid creates a more variable power supply and less consistent load patterns for utility companies to try and accommodate.

And as more and more electric vehicles plug in, this increased load on the grid could risk a mismatch in the supply and demand of electricity, potentially leading to system-wide failures.

Building standard power grid practices

Today’s power grid is an aging infrastructure in desperate need of a major overhaul, it is inadequately prepared for this revolution in energy and transportation.

It’s overstrained and requires significant modernisation to improve efficiency and resilience.

About the Author: Thomas Goetzl is vice president and general manager for Automotive and Energy Solutions (AES) of the Electronic Industrial Solutions Group at Keysight as well as managing director of Keysight Technologies in Germany. Tom was most recently the AES Business Manager for power applications focusing on test solutions for Smart Grid, Power Semiconductors, Batteries, and EV/HEV. During his time with HP, Agilent Technologies, and now Keysight Technologies, Tom has managed R&D projects, developed sales channels for remote server management products. In 2012, Tom became the worldwide marketing manager for Electronic Test Division (ETD).

With this complexity, power grid stakeholders must operate in a standardised, more imaginative fashion to manage the influx of electric vehicles in the next decade.

We must create standards allowing electric vehicles to serve as an active participant in ensuring the health of the power grid rather than being merely a burdensome load.

This form of relationship between the grid and electric vehicles can be realised through vehicle-to-grid (V2G) power transfer.

New intelligent power conversion technology and utility communication capabilities built into EVs and EV charging stations enable V2G and allow for cars to communicate with and help stabilise the power grid by using the EV’s onboard battery as a grid-tied energy storage system.

But regulatory hurdles currently stand in the way of V2G – EVs and EV charging stations will ultimately need to meet new and evolving standards for DER interconnection and interoperability with the power grid.

This will ensure utility operators have the tools they need in EV charging systems to help manage the proliferation of EVs, using them as a resource to accommodate the diverse energy mix and shifting demands of the modern power grid.

They could charge but also disperse excess power back to the grid, improving the overall resilience.

Shifts in materials, manufacturing

Traditional automobiles feature large amounts of metal in their construction, both in their body and engine parts.

Electric vehicles require large amounts of other elements, including nickel, manganese, carbon, and lithium (for the batteries).

These materials are in short supply, both from existing global supply chain challenges and the lack of these resources to support something as significant as the global automotive industry.

The road forward

Electric vehicles offer a tremendous opportunity to reshape transportation and lessen the automotive industry’s impact on the planet.

Stakeholders must continue to find innovative solutions to solve the numerous ancillary concerns that come with the influx of electric vehicles into the marketplace.

Standardising energy use, updating manufacturing processes, and battery creation will go a long way toward creating a sustainable industry.

We must remember that electric vehicle technology is still nascent, especially compared with its combustion-engine forefathers.

Crucial to the changes in manufacturing and materials are the car batteries themselves.

Battery cells account for about 30 percent of an electric vehicle’s cost and feature a level of complexity mainly unknown to most manufacturers regarding testing, cell measurement, and other factors.

Lithium-ion car batteries have performed better than experts originally predicted.

Early tests pushed many manufacturers away, feeling it would not become a viable technology.

While some companies like Tesla forged ahead, many now find themselves playing catchup.

Electric vehicle batteries must not only operate the vehicle but also not become a scourge on the environment.

The car batteries must remain safe for use but also safe 30 years from now.

The goal of EV and cell manufacturers should not only be to take emission-emitting vehicles off the road but to also improve manufacturing processes to create a green sustainable product.

That requires still more testing, measuring, standardisation, and data and analytics to perfect these technologies.

Along with production, these batteries and other car components must feature highly recyclable elements to ensure long-term sustainability.

Tags: electric vehicles, EV, infrastructure, insights, Keysight, opinions, Tech Focus, technology, vehTech

It’s a brave new world baring down on us with the advent of EVs. It’ll certainly require a paradigm change in thinking, especially in the infrastructure.

Couldn’t agree more. That’s why we need to look ahead at the changes to better prepare and anticipate any potential roadblocks (forgive the pun).

🙂